Founded in 1853, Devold is Norway's leading high-quality wool clothing brand, with garments rigorously tested in challenging winter conditions. About 40 percent of its wool products are sold internationally, primarily within the European market, not least the protective work wear series used by fire fighters, police and defense, and the supplier industry to the oil rigs in the North Sea.

Ensuring supply chain transparency and vertical integration

At a time when many brands are just starting to map and disclose tier one and two suppliers, Devold is a front runner with an already fully traceable supply chain.

“Adopting the ETI reporting requirements aligns with our commitment to sustainable business practices and traceability as matters of quality. More than 60% of our wool is traceable back to the very farm of origin, and our garments carry the name of the producing farm. These equal partnerships with selected wool farmers secure consistent wool quality and that both animals and land are well taken care of,” Devold’s Chief Sustainability Officer, Trude Ertresvåg, said.

Devold’s owners, the Flakk family, practice vertical integration by owning and operating Devold’s factory and dyeing plant in Lithuania. This offers visibility into tiers three and four – suppliers providing raw materials to tier three facilities for processing (scouring and top-making).

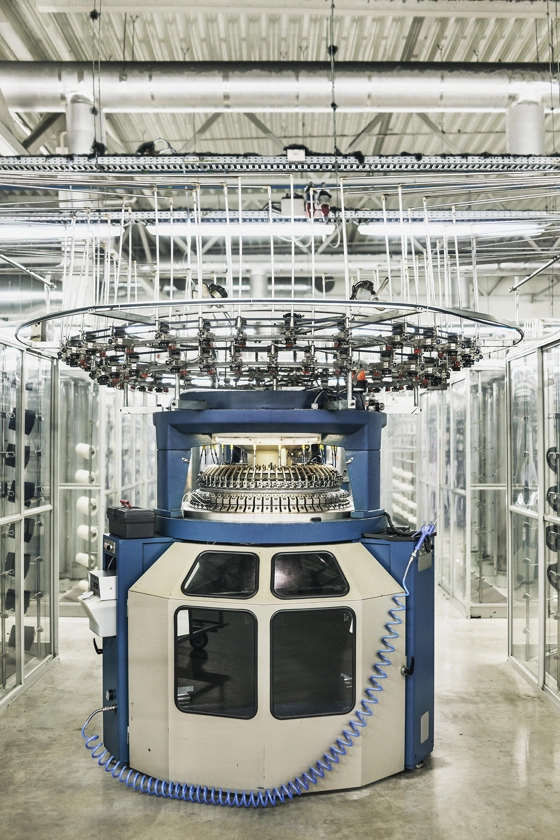

Vertical integration comes with direct responsibility for all the people making their products. Devold operates a fully controlled process, “we knit the fabric, we cut the fabric, we sow the garments, we add the finishing and, importantly, we pay our staff a living wage.”

Wages at Devold have doubled wages since 2018 to keep pace with inflation and ensure that staff do not experience a real wage decrease.

Collaboration to increase leverage

Attracted by ETI’s tripartite structure and ability to convene a diverse range of key stakeholders, Ertresvåg said “Devold sees merit in increasing our leverage where we alone can lack the operational control or sufficient volume to effectively incentivise change.”

“Collaboration is essential to succeed with responsible sourcing. We might have an order of buttons that equals an hour’s work for a supplier every month. In such cases, it is obvious that we need to combine purchasing power across the industry to drive positive change in the supply chain,” she said. “ETI will also hold us to account to ensure our purchasing practices are sound and that we are achieving the standard of practice we set out to.”

The update of Devold of Norway’s human rights statement is necessary to ensure the company meets the requirements of ETI's base codes that are reviewed periodically.

Timing of the membership application

Devold’s decision to apply for membership has also been influenced by emerging EU and national legislation on due diligence. We want to lend our voice to the ETIs due diligence methodology and influence others to join and improve business, human rights, and environmental impacts across the industry.

“We’re delighted to have Devold join the ETI fold”, said Peter McAllister, Executive Director, ETI. “I have no doubt they will bring a wealth of experience and good practice to share with fellow members. As new members, Devold will be expected to implement all the policies, resources and strategies contained in the foundation stage of ETI’s Progression Framework. We look forward to working with them and supporting their ethical trade journey.”